Trusted company that deals in quality-made products

Showroom

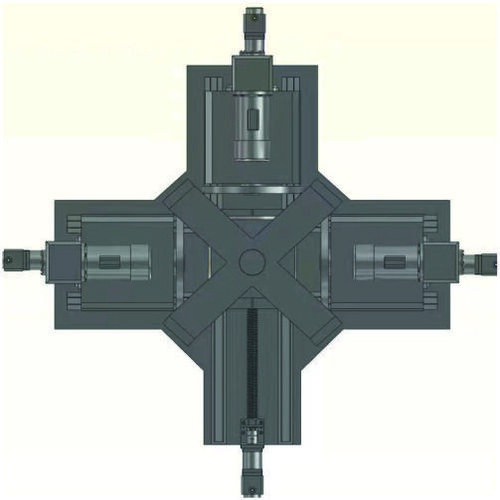

Notable for their four column body, these Tee Forming Machines use stainless steel, carbon steel, aluminum and brass as their raw materials. PLC controlled operation, multi cylinder based operation, hydraulic mechanism for avoiding leakage and sturdy construction are some of the main features of these machines.

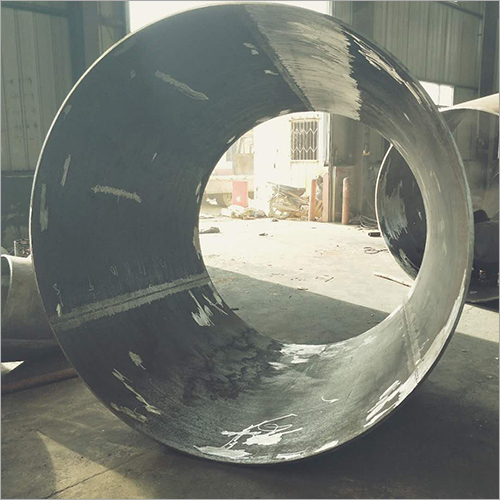

Available with axial and radial hot rolling principle based operating mode options, these Ring Rolling Machines are preferred for their high output level. These systems adopt hydraulic rolling force for their operation. Dual arms of their centering section are controlled by hydraulic cylinders for maintaining proper position of rings.

These vertical Elbow Making Machines are required to develop round shaped stainless steel or carbon steel elbows for air conditioner and ventilation equipment. These use hydraulic force for their operation. Adjustable parameters, hardened movable parts and high speed operation are the main features of these machines.

The offered Pipe Mandrel & Moulds are used as essential parts of exhaust pipes for automobiles. Developed from durable steel having exceptional strength, these products are reckoned for their global standard, long working life, ease of fitting and advanced production method.

This Shot Blasting Machine is widely used for cleaning and polishing or strengthening stainless steel plates, H beam and I beam structures, square tubes and so on. This machine is equipped with blasting chamber, cleaning chamber, roller conveyor and dust collector to name a few.

This Seamless Pipe Machine is used for producing bulk amount of round drill pipes by using advanced hot rolling technique. Error free operation, ability to maintain uniform wall thickness of produced pipes, low noise function, user friendly design and low operating cost are its main attributes.

Accessories like Pipe Fittings are used to alter flow direction of fluids or gases transmitted through pipelines. Accessible in different end connection design options, these pipe fitting components can be installed in different angles.

Beveling Machine is used for preparing pipe ends prior to their welding. Standard angular position is maintained at the end of tube or pipe. This easy to operate machine helps to save labor cost for its high speed operation and smooth functioning.

This high performance Beveling Machine is used for precise bending of stainless steel, mild steel, CRC and brass pipes. This system is used for producing gym equipments, furniture and automobile parts. This machine can maintain 0 to 180 degree bending angle of pipes.

This Cold Forming Machine is used for producing stainless steel and carbon steel elbows and tees. This machine consists of powerful hydraulic pump, main cylinder, oil pump and side cylinder. Long working life, uninterrupted operation and long working life are its main attributes.

Hot Forming Machine is used for maintaining precision of shape of automotive brackets, ducts, stiffeners used in aerospace arena and angles by using single piece of metal. Advanced stress relieve technique is used to prevent spring back of produced parts.

Easy to operate Hydraulic Press Machine is used for executing procedures like forming, deep drawing, straightening and punching of metal components. This equipment is also utilized for transfer molding, broaching and bonding jobs. Adjustable parameters, enclosed structure of its hydraulic system and uniform pressure distribution arrangement are its main features.

This meticulously designed Hydraulic Cap Machine is preferred for its high automation degree and global standard. Equipped with advanced hydraulic components, this machine is safe to operate. User friendly design, long working life, mechanical controlling system and high performance are its main attributes.

We are a renowned name that offers best-in-class Cold Forming Elbow Machines that utilize cold forming processes to manufacture elbows from metal pipes without applying heat, maintaining material properties. They are commonly used in industries like plumbing and HVAC for precise and efficient elbow production.

Cold Forming Tee Machine units availed by our company are employed in pipe fabrication to create tees via cold forming techniques, preserving material integrity. They are ideal for manufacturing tees with accuracy and consistency in various industries like oil and gas.

Our high-performance Hot Forming Elbow Machines utilize heat to shape metal pipes into elbows, enhancing ductility for complex bends. Often used in heavy industries like shipbuilding and chemical processing for high-strength elbow production.

Socket weld pipe fittings are produced for strong and leak-proof pipe connections. Designed for high-pressure applications, they offer excellent strength, smooth flow paths, and long service life, making them suitable for critical industrial and process piping systems.

Stainless steel pipe fittings are manufactured for secure and corrosion-resistant connections in piping systems. Designed for strength and precision, they support smooth fluid flow, withstand high pressure, and ensure long service life. These fittings are widely used in industrial, chemical, and process applications.

Two half pipe fittings are produced for quick installation and reliable jointing of pipelines. Engineered for accuracy and durability, they offer strong grip, leak-free performance, and ease of assembly. These fittings are suitable for maintenance, repair, and industrial piping applications.

Bending machines are manufactured for shaping pipes, tubes, and metal sections with high accuracy. Featuring robust construction and efficient operation, they deliver consistent bends, reduced material wastage, and reliable performance for fabrication, engineering, and industrial production environments.

Flange marking machines are produced for permanent and accurate marking on flanges. Designed for industrial use, they ensure clear identification, traceability, and compliance with standards while offering durability, precision operation, and efficient performance in manufacturing units.

Pipe fitting marking machines are manufactured to mark product details, sizes, and grades on fittings. With precise marking capability and rugged design, they ensure readability, consistency, and long-term durability, supporting quality control and traceability in industrial operations.

Valve CNC lathe machines are produced for precision machining of industrial valves. Equipped with advanced controls and rigid construction, they ensure high accuracy, repeatability, and efficient production, meeting the demands of valve manufacturing and heavy engineering industries.

Alloy steel pipe fittings are manufactured for high-pressure and high-temperature applications. Known for superior strength, wear resistance, and durability, they provide reliable performance in power plants, refineries, and heavy industrial piping systems.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free