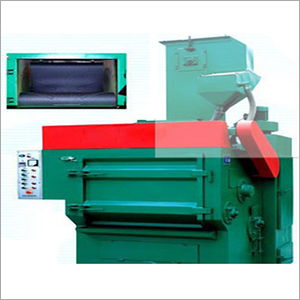

Steel Pipe Shot Blasting Machine

Product Details:

- Product Type Shot Blasting Machine

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Polished

- Color Blue

- Warranty 1 Year

- Usage & Applications Industrial

- Click to view more

X

Steel Pipe Shot Blasting Machine Price And Quantity

- 1000 , , Piece

Steel Pipe Shot Blasting Machine Product Specifications

- Polished

- Blue

- 1 Year

- Automatic

- Electricity

- Shot Blasting Machine

- Industrial

Steel Pipe Shot Blasting Machine Trade Information

- 100000 , , Piece Per Day

- 15-25 Days

Product Description

Owing to the expertise in this domain, we are offering an excellent quality Steel Pipe Shot Blasting Machine. It is widely use for cleaning new or used seamless steel pipes. It is manufactured by making use of optimum grade materials with the aid of current techniques under the experts' supervision. The offered Steel Pipe Shot Blasting Machine is available in a range of technical specifications as per the application needs of clients.

Features:

- High operational fluency

- Impeccable performance

- Negligible maintenance

|

Tech |

QG |

QG |

|

Type |

QGW20-50 |

QGW80-50 |

|

Dia of pipe tube (mm) |

30-500 |

250-1500 |

|

Abrasive flow rate (kg/min) |

2x250 |

2x250 2x270 |

|

Cleaning speed (m/mm) |

0.5-5 |

0.5-4 1-10 |

Automated Precision for Pipe Surface Treatment

This machine leverages advanced shot blasting technology to deliver consistent, high-quality surface polishing for steel pipes. Automatic controls reduce labor and enhance productivity, making it ideal for demanding industrial environments. The polished finish not only improves aesthetics but also prepares the pipes for painting, coating, or further processing, contributing to extended lifespan and better corrosion protection.

Versatile Industrial Applications

Designed for heavy-duty settings, the steel pipe shot blasting machine meets the requirements of construction, oil and gas, power generation, and manufacturing sectors. Its robust build and reliable operation make it a preferred choice for companies seeking to improve efficiency and output quality. Distributors and suppliers in China ensure prompt availability and after-sales support across global markets.

FAQ's of Steel Pipe Shot Blasting Machine:

Q: How does the steel pipe shot blasting machine operate automatically?

A: The machine utilizes programmed electrical controls to automate the shot blasting process. Once the pipes are loaded, it manages the blasting, polishing, and cleaning cycles without manual intervention, ensuring consistent and uniform surface treatment.Q: What is the primary benefit of using electricity as the power source for this machine?

A: Operating on electricity provides stable and efficient power delivery, allowing for uninterrupted automatic functioning. This improves productivity and ensures the shot blasting process maintains consistent quality while reducing maintenance compared to mechanical or pneumatic alternatives.Q: When should steel pipes undergo shot blasting treatment?

A: Steel pipes should be treated prior to painting, coating, welding, or installation. Shot blasting removes rust, mill scale, and impurities, creating a polished surface that enhances paint adhesion and extends the pipe's service life.Q: Where can I purchase this steel pipe shot blasting machine?

A: The machine is available through reputable distributors, exporters, manufacturers, suppliers, and traders based in China, offering both domestic and international delivery options. Assistance with installation and after-sales service is also available.Q: What is the process followed during steel pipe shot blasting?

A: The machine automatically feeds steel pipes into the blasting chamber, where abrasive media is propelled at high speed to clean and polish the surface. Dust and debris are collected, leaving the pipes with a smooth, polished finish suitable for further industrial use.Q: How does polished surface treatment benefit industrial applications?

A: Polished surfaces prevent corrosion, improve paint or coating adhesion, and facilitate easier inspection and maintenance. This leads to longer-lasting pipes and reduces the risk of failure in demanding environments, making it a cost-effective solution for industrial users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry