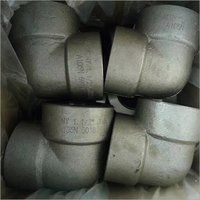

Socket Weld Pipe Fitting

Product Details:

- Product Type Union

- Material Stainless Steel

- Connection Welding

- Shape Round

- Section Shape Round

- Color Silver

- Warranty Yes

- Click to view more

Socket Weld Pipe Fitting Price And Quantity

- 10 Piece

Socket Weld Pipe Fitting Product Specifications

- Welding

- Yes

- Silver

- Stainless Steel

- Round

- Union

- Round

Socket Weld Pipe Fitting Trade Information

- 1000 Piece Per Month

- 7 Days

Product Description

- Rugged design

- High strength

- Easy installation

- Precise dimensions

Frequently Asked Questions

1. A socket weld fitting is what?

Ans - Reducers, tees, and elbows are among the fittings and pipes that are welded using socket welding (SW). In order to permanently unite pipes that are put into a recess in the fitting, flange, or valve, socket weld pipe fittings are employed. Once the pipe has been properly placed, sealing welds of the fillet kind are used to connect it to the fitting.

2. What distinguishes screwed fittings from socket welds?

Ans - Threaded fittings are screwed onto the pipe, whereas socket weld fittings are attached to pipes by fillet welds (or vice-versa). A threaded fitting with a socket weld fitting (left side) (right side). In situations when reliable connections are needed, socket weld fittings are employed.

3. What are the drawbacks of socket welding?

Ans - In the food industry, socket welding is not acceptable since it does not allow for full penetration and leaves overlaps and fissures that are very difficult to clean, leading to virtual leaks.

4. What operating pressure do socket weld fittings have a rating for?

Ans - The pressure ratings for socket weld fittings typically range from 3000 pounds to 6000 pounds to 9000 pounds. The socket weld fitting's most popular sizes range from 1/2 inch to 4 inch. Most of these pressure fittings aren't used for lengths longer than 4 inches.

Premium Stainless Steel Construction

Constructed from top-grade stainless steel, our socket weld pipe fittings offer excellent resistance to corrosion and wear. This material choice guarantees reliability and longevity in both standard and extreme conditions, making them perfect for a wide array of industrial piping systems.

Secure and Durable Welding Connection

Socket weld fittings are engineered for a strong, welded joint, ensuring a seamless connection for round pipes. The welding process not only enhances mechanical strength but also minimizes leakage risks, supporting safe operation in high-pressure applications.

FAQ's of Socket Weld Pipe Fitting:

Q: How are socket weld pipe fittings installed?

A: Socket weld pipe fittings are installed by inserting the pipe into the fitting's socket and then welding around the joint. This method creates a strong, permanent bond suitable for high-pressure pipelines.Q: What are the benefits of using stainless steel for these pipe fittings?

A: Stainless steel offers superior resistance to corrosion, heat, and mechanical stress, making it ideal for harsh, demanding environments. It also provides a long service life and maintains its appearance over time.Q: When should I use socket weld pipe fittings instead of threaded fittings?

A: Socket weld fittings are preferred when a leak-proof, high-strength connection is required, especially in high-pressure or critical service environments where threaded joints may not offer adequate integrity.Q: Where can these stainless steel socket weld fittings be used?

A: These fittings are commonly used in chemical processing, oil and gas, food and beverage, and other industries that require durable and hygienic piping solutions for fluids and gases.Q: What is the process for ensuring fitting quality?

A: Each fitting is manufactured following strict quality controls, including precise machining, rigorous material testing, and compliance with international standards, ensuring optimal performance and reliability.Q: How does the warranty benefit customers?

A: The warranty offers customers peace of mind by assuring product quality and support for any manufacturing defects, reinforcing confidence in the durability and reliability of the fittings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry