Elbow Beveling Machine

Product Details:

- Product Type Elbow Beveling Machine

- Power Source Electricity

- Operating Type Automatic

- Power 9 Watt (w)

- Surface Treatment Polished

- Dimension (L*W*H) 1.5 x 1.5 x 1.6 Meter (m)

- Weight (kg) 2.1 Tonne

- Click to view more

Elbow Beveling Machine Price And Quantity

- 1000 , , Piece

Elbow Beveling Machine Product Specifications

- Elbow Beveling Machine

- Green

- Polished

- 1.5 x 1.5 x 1.6 Meter (m)

- Automatic

- 2.1 Tonne

- 1 Year

- Industrial

- Electricity

- 9 Watt (w)

Elbow Beveling Machine Trade Information

- 100000 , , Piece Per Day

- 15-25 Days

Product Description

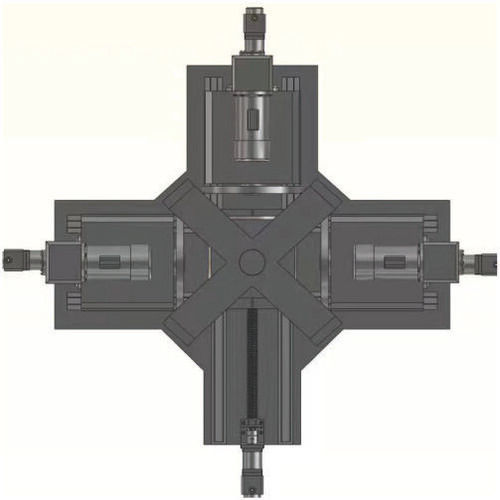

Elbow Beveling Machine

|

|

YWDJ 2503A |

YWDJ 3204B |

YWDJ 4008A |

YWDJ 4010B |

YWDJ 5012B |

YWDJ 5016A |

YWDJ 6324A |

YWDJ 6332B |

YWDJ 8036A |

|

Processing Size Range (inch) |

1/2-3'' |

1-4'' |

3-8'' |

4-10'' |

5-12'' |

8-16'' |

12-24'' |

22-32'' |

28-36'' |

|

Max Processing Thickness (SCH) |

SCH80 |

SCH80 |

SCH80 |

SCH80 |

SCH80 |

SCH80 |

SCH80 |

SCH80 |

SCH80 |

|

Spindle Moving Type |

Hydraulic Stepless Speed Control |

Hydraulic Stepless Speed Control |

Hydraulic Stepless Speed Control |

Hydraulic Stepless Speed Control |

Hydraulic Stepless Speed Control |

Hydraulic Stepless Speed Control |

Hydraulic Stepless Speed Control |

Hydraulic Stepless Speed Control |

Hydraulic Stepless Speed Control |

|

Workpiece Clamping Type |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

|

System Pressure (Mpa) |

7 |

7 |

7 |

7 |

7 |

7 |

7 |

7 |

7 |

|

Overall Dimension (M) |

1.5*1.5*1.6 |

1.75*1.75*1.9 |

2.1*2.1*2.2 |

2.3*2.3*2.4 |

2.5*2.5*2.8 |

2.9*2.9*3.0 |

3.5*3.5*3.8 |

3.9*3.9*4.0 |

4.3*4.3*4.5 |

|

General Power (KW) |

9 |

12 |

19 |

19 |

26 |

34 |

65 |

80 |

98 |

|

Weight (T) |

2.1 |

2.8 |

6.3 |

6.5 |

7.2 |

9.7 |

16 |

21 |

|

Efficient Automated Beveling

The automatic operating system ensures consistent, high-quality bevels on elbows with minimal manual intervention. This results in higher productivity and uniform output, which is essential for industrial environments. The machine's precision components are built to sustain long-term performance, making it a dependable addition to any manufacturing facility.

Industrial-grade Durability

With a polished finish and a weight of 2.1 tonnes, the Elbow Beveling Machine is engineered for heavy-duty industrial use. Its robust construction not only enhances longevity but also stands up to rigorous working conditions. The green, corrosion-resistant exterior further increases its lifespan and visual appeal.

FAQ's of Elbow Beveling Machine:

Q: How does the Elbow Beveling Machine operate automatically?

A: The machine is equipped with an automatic control system that manages the entire beveling process without manual intervention. Simply set your desired parameters, and the machine handles feeding, cutting, and finishing with precision for consistent results.Q: What are the main industrial applications of this machine?

A: This device is primarily used for beveling elbows in pipelines, which is essential in industries such as oil and gas, chemical processing, and water treatment plants. It efficiently prepares joints for welding and assembly.Q: When should I perform maintenance on the machine?

A: Regular maintenance is recommended every three months to ensure optimal performance. However, refer to the included manufacturer's guide for specific schedules based on usage frequency and operating conditions.Q: Where is this machine manufactured and distributed?

A: The Elbow Beveling Machine is manufactured and supplied by trusted distributors, exporters, and traders across India. It is available for industrial procurement nationwide.Q: What is the process of beveling with this machine?

A: The process involves securing the elbow component, selecting appropriate settings, and allowing the machine to automatically feed and bevel the material. Its precise mechanics ensure clean, accurate edges suitable for subsequent welding or assembly.Q: How is the machine powered, and what is its energy consumption?

A: It uses electricity as its power source with a consumption of 9 watts, making it efficient and suitable for continuous industrial operation without incurring substantial energy costs.Q: What are the key benefits of using this automated beveling machine?

A: The key advantages include improved accuracy, reduced labor costs, and higher throughput. Its sturdy, polished construction and automatic features minimize downtime, providing consistent performance and enhancing workplace safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free