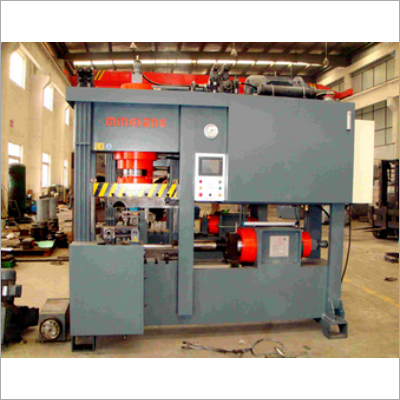

Elbow Cold Push Forming Machine

Product Details:

- Material Mild Steel

- Computerized No

- Automatic Grade Automatic

- Control System Human Machine Interface

- Color Grey

- Warranty 1 Year

- Click to view more

X

Elbow Cold Push Forming Machine Price And Quantity

- 1000 , , Piece

Elbow Cold Push Forming Machine Product Specifications

- Mild Steel

- 1 Year

- Human Machine Interface

- No

- Grey

- Automatic

Elbow Cold Push Forming Machine Trade Information

- 100000 , , Piece Per Day

- 15-25 Days

Product Description

This PLC controlled automatic Elbow Cold Push Forming Machine is required for cold push molding by using stainless steel and carbon steel. This machine consists of advanced side pushing cylinder, die closing cylinder and demolding section. Ergonomic design of its pushing rods, mandrels and molds help to maintain precision of produced elbows by ensuring their uniform wall thickness level. The hydraulic control section of this machine is useful for saving energy and for optimizing its performance. Ease of changing molds, stable operation and standard quality are its main attributes. We are a reliable manufacturer and exporter of Elbow Cold Push Forming Machine.

Features

- This machine uses alloy steel, stainless steel and carbon steel as its raw materials.

- Shot blasted surface

- User friendly design

- Long working life

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry