Trusted company that deals in quality-made products

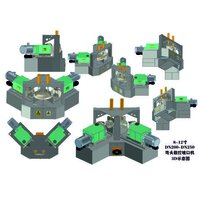

Two Head Beveling Machine

Product Details:

- Product Type Beveling Machine

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Polished

- Color White Black

- Warranty 1 Year

- Usage & Applications Industrial

- Click to view more

X

Two Head Beveling Machine Price And Quantity

- 1 Set

Two Head Beveling Machine Product Specifications

- Polished

- Automatic

- Beveling Machine

- 1 Year

- Industrial

- White Black

- Electricity

Two Head Beveling Machine Trade Information

- 15 Set Per Month

- 25-60 Months

Product Description

A two-head beveling machine is a piece of equipment used in metalworking, particularly in the fabrication and welding industries. This machine is designed to create beveled edges on metal workpieces, which is crucial for welding preparation as it allows for better joint penetration and stronger welds.

Heres a brief overview of how a two-head beveling machine typically works:

1. Setup: The workpiece is securely clamped or held in place on the machine's work surface.

2. Beveling: The two heads of the machine simultaneously cut or grind the edges of the workpiece at the desired angle to create a beveled edge. The use of two heads allows for faster processing and increased efficiency.

3. Adjustability: These machines often offer adjustable settings for the angle and depth of the bevel, allowing operators to customize the bevel according to the requirements of the welding project.

4. Automation: Some two-head beveling machines may feature automation capabilities, such as programmable settings or CNC (Computer Numerical Control) control, which enable precise and consistent beveling operations.

5. Safety: Safety features such as guards and emergency stop buttons are typically incorporated into the design to ensure the safety of operators during operation.

Efficient Dual-Head Operation

Equipped with two beveling heads, this machine simultaneously processes multiple edges, boosting both throughput and accuracy. Its automatic mechanisms reduce manual labor, ensuring reliable surface treatments and consistent results in demanding fabrication environments.

Durability and Warranty Assurance

Constructed with robust materials and finished with a polished treatment, the Two Head Beveling Machine offers long-lasting performance. Backed by a 1-year warranty, users can rely on its quality and support for industrial needs, whether as manufacturers, suppliers, or exporters.

FAQ's of Two Head Beveling Machine:

Q: How is the Two Head Beveling Machine used in industrial settings?

A: This machine is employed to bevel the edges of metal components automatically, enhancing finish quality and preparation for subsequent fabrication steps. Its dual-head design increases efficiency and reduces processing time, making it ideal for high-volume production environments.Q: What are the main benefits of using an automatic two head beveling machine?

A: Automatic operation streamlines the beveling process, minimizes manual intervention, and ensures consistent surface treatment. The dual heads allow simultaneous processing, leading to higher productivity and improved edge quality across industrial applications.Q: Where is this machine typically supplied from and who are the intended users?

A: The Two Head Beveling Machine is typically distributed, exported, manufactured, and supplied from China. It is intended for industrial users such as manufacturers, suppliers, traders, and exporters seeking reliable edge processing solutions.Q: When should I consider using a two head beveling machine in my operation?

A: You should integrate this machine when your production requires rapid, consistent edge beveling for metal parts, especially in high-volume or automated fabrication lines. Its features are suitable for processes demanding efficiency and polished finishes.Q: What is involved in the operation and maintenance process of this machine?

A: Operation is fully automatic-simply set the parameters and the machine will perform beveling tasks routinely. Maintenance involves regular electrical checks, surface cleaning, and inspections to ensure optimal performance, supported by a 1-year warranty for any manufacturing defects.Q: How does the polished surface treatment of the machine benefit daily usage?

A: The polished surface not only enhances the machine's appearance but also offers increased resistance to corrosion and wear, ensuring longevity. This finish simplifies cleaning and maintenance, sustaining performance in harsh industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free