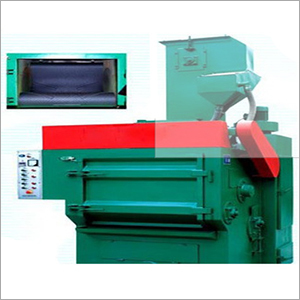

Automatic Shot Blasting Machine

Product Details:

- Product Type Shot Blasting Machine

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Polished

- Weight (kg) 1100 Kilograms (kg)

- Color Green

- Warranty 1 Year

- Click to view more

Automatic Shot Blasting Machine Price And Quantity

- 1000 , , Piece

Automatic Shot Blasting Machine Product Specifications

- Electricity

- 1 Year

- Automatic

- Industrial

- Green

- Polished

- Shot Blasting Machine

- 1100 Kilograms (kg)

Automatic Shot Blasting Machine Trade Information

- 100000 , , Piece Per Day

- 15-25 Days

- East India

Product Description

Banking on our hi-tech manufacturing facilities, we are affianced in providing our clients superior quality Automatic Shot Blasting Machine. This is manufactured with high precision by making use of optimum grade materials and latest technology. It is best for removing metal mill scale, carbide black, surface dirt of metal or non-metal items.. They are highly appreciated for being sturdy and durable. We offer this Automatic Shot Blasting Machine in different technical specifications as per the demands of our clients at affordable rates.

Features:

- Easy to move, with complete accessories and function, easy operation.

- High surface cleaning and finishing efficiency as long as equipped with compressed air source.

- Using imported blast valve structure, easy to adjust the proportion of air and sand, optimizing the utilization rate of abrasive sand.

Specifications:

|

Pot Volume |

0.05m3 |

|

Diameter of roller |

400 |

|

Load Capacity |

150Kg |

|

Weight (kg) |

1100Kg |

|

Maximum weight of single piece(kg) |

5Kg |

|

Pill impelling volume(Kg/min) |

40Kg/min |

|

Ventilation capacity(m3/h) |

2000m3/h |

|

Productivity(t/h) |

0.3-0.6t/h |

|

Total power dissipation(KW) |

6KW |

|

Feeding Amount |

80Kg |

Enhanced Surface Treatment Efficiency

Engineered for automatic operation, this shot blasting machine ensures uniform surface treatment of metals, reducing manual labor and increasing throughput. With its polished green exterior and sturdy construction, it's a reliable choice for busy industrial settings. The machine delivers consistent results, vital for industries where quality and productivity are paramount.

Dependable Operations with Electrical Power

Powered by electricity, this shot blasting machine offers stable and energy-efficient performance. Electrical operation ensures compatibility with most industrial setups and reduces dependence on fossil fuels, contributing to a cleaner working environment. The 1,100 kg design provides balance and durability during extended use.

FAQ's of Automatic Shot Blasting Machine:

Q: How does the automatic shot blasting machine improve industrial surface treatment?

A: This machine uses automatic operation to deliver consistent and thorough surface cleaning, strengthening, and polishing. By automating these processes, it reduces human error, speeds up production, and provides high-quality, repeatable finishes.Q: What is the typical process for operating this electric shot blasting machine?

A: Operation begins by loading metal parts into the machine. Once activated, the machine automatically propels abrasive media onto surfaces to achieve the desired finish. The process is controlled via preset parameters for optimal results with minimal manual intervention.Q: When should the automatic shot blasting machine be used in manufacturing?

A: It is best utilized before painting, coating, or welding metal parts. Using the machine at this stage ensures surfaces are free of contaminants and have the required texture for subsequent production steps.Q: Where is this shot blasting machine commonly employed?

A: The machine is widely used in industrial environments such as steel fabrication plants, automotive manufacturing facilities, and construction equipment production units. Its efficiency makes it suitable for both large-scale and specialized surface treatment tasks.Q: What are the main benefits of using this automatic shot blasting machine?

A: Key benefits include enhanced productivity, reduced manual labor, consistent quality finishes, and efficient consumption of abrasive materials. The 1-year warranty further ensures reliable performance and long-term value for industrial operations.Q: How can I obtain the shot blasting machine if I am outside China?

A: As a product distributed, exported, and supplied worldwide, you can contact authorized distributors, exporters, or manufacturers based in China to arrange shipment to your location, ensuring global access and support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry