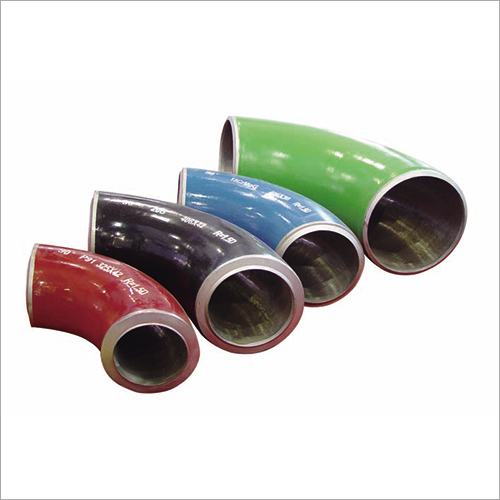

Alloy Steel Pipe Fittings

Product Details:

- Temperature Range -20C to 600C

- Thread Type NPT, BSP, BSPT

- Flexibility Rigid

- Sealing Type Metal to Metal

- Connection Type Butt Weld, Socket Weld, Threaded

- Tensile Strength 415 MPa - 585 MPa

- Diameter 15 mm to 1200 mm

- Click to view more

Alloy Steel Pipe Fittings Product Specifications

- Alloy Steel Pipe Fittings

- Alloy Steel

- Oil & Gas, Power, Petrochemical, Chemical, Fertilizer, Refinery

- Round

- 1/2 to 48 (DN15-DN1200)

- Alloy Steel Grade WP5, WP9, WP11, WP22, WP91

- Black Painted, Galvanized, Sand Blasted

- Black, Grey

- Customized as per order

- -20C to 600C

- NPT, BSP, BSPT

- Rigid

- High Pressure, High Temperature, Corrosive Environment

- 2 mm to 36 mm

- Metal to Metal

- Elbow, Tee, Reducer, Coupling, Cap

- ASTM A234 WP5 / WP9 / WP22 / WP91, ASME B16.9/B16.11

- 15 mm to 1200 mm

- 415 MPa - 585 MPa

- SCH 10 to SCH 160, XXS

- Butt Weld, Socket Weld, Threaded

- Butt Welded, Socket Welded, Threaded

- Black Paint, Anti-Rust Coating

- 0.5 mm

- 1.5D, 2D, 3D & Custom

- 205 MPa - 450 MPa

Alloy Steel Pipe Fittings Trade Information

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- All India

Product Description

- Robust construction for enhanced durability

- Resistant to high pressure

- Quick and easy installation

- Corrosion resistance

Frequently Asked Questions

1. Alloy steel pipe fittings: what are they?

Ans - Manufacturer and Exporter of Alloy Steel Pipe Fittings in China

It is mostly used for pipes with nominal sizes of NPS 2 or less and tiny pipe diameters. It has a tensile strength that is higher than that of stainless steel, ranging from 758 to 1882 MPa.

2. Are alloys preferable than stainless steel?

Ans - Comparatively speaking, alloy steel is more durable than stainless steel. Compared to stainless steels, alloy steels are simpler to weld. Although stainless steel can be welded, it is not as simple a process as other welds. Comparing alloy steel to conventional stainless steel grades, alloy steel is less expensive and easier to process.

3. Does alloy steel not rust?

Ans - Rust will occur in an alloy if it contains ferrous metal (iron). Any metal alloy can corrode. When we expose the metal to air and moisture, it rusts, forming an iron oxide layer.

4. Carbon steel or alloy steel, which is stronger?

Ans - Low-carbon steel has a tensile strength of roughly 450 MPa, while high-carbon steel has a tensile strength of 965 MPa. Compared to carbon steel, alloy steel has a higher tensile strength. Alloy steel has a tensile strength range of 758 to 1882 MPa.

Robust Manufacturing Process

Our alloy steel pipe fittings are crafted through advanced forging, seamless, and welded techniques, ensuring exceptional strength and uniformity. Each fitting undergoes strict heat treatments, including normalization, quenching, tempering, and annealing, to achieve precise tolerances and optimal mechanical properties. Thorough inspections, such as 100% radiography and ultrasonic testing, guarantee reliability and safety for critical applications.

Versatile Shapes and Connections

The product range encompasses elbows, tees, reducers, couplings, and caps, designed with round sections for seamless integration. Connection types include butt welded, socket welded, and threaded options-compatible with NPT, BSP, and BSPT thread forms-to suit diverse project needs. Offered in various diameters from 15 mm to 1200 mm and lengths customized per order, these fittings adapt to complex system layouts.

Superior Performance and Durability

High corrosion and impact resistance, coupled with excellent tensile and yield strength, make these fittings ideal for harsh and corrosive environments. With a rated service life of up to 15 years and a temperature range spanning -20C to 600C, they maintain structural integrity in oil & gas, power, petrochemical, chemical, fertilizer, and refinery operations.

FAQ's of Alloy Steel Pipe Fittings:

Q: How are alloy steel pipe fittings inspected for quality assurance?

A: Alloy steel pipe fittings undergo comprehensive inspection methods such as 100% radiography, ultrasonic testing, and detailed visual and dimensional checks, ensuring compliance with stringent industry standards and consistent product reliability.Q: What end types and connections are available for these fittings?

A: These fittings are offered in beveled, plain, and threaded end types, compatible with butt weld, socket weld, and threaded connections. Threaded options support NPT, BSP, and BSPT threads, providing flexibility for varied system configurations.Q: When should I use alloy steel pipe fittings in my application?

A: Alloy steel pipe fittings are recommended for use in high-pressure, high-temperature, or corrosive process environments such as oil & gas, power generation, petrochemical, chemical, and fertilizer plants, where durability and safety are crucial.Q: What manufacturing processes are utilized for these pipe fittings?

A: The fittings are produced using forging, seamless, and welded manufacturing techniques. Each method yields reliable products with high mechanical strength, suitable for heavy-duty industrial applications.Q: Where can these fittings be applied most effectively?

A: Their robust construction and superior resistance make them ideal for installation in pipelines handling hazardous or aggressive fluids, typically found in industries like oil & gas transmission, power, petrochemical refining, and chemical processing.Q: What benefits do these alloy steel fittings provide over standard pipe fittings?

A: They provide enhanced corrosion and impact resistance, longer service life up to 15 years, and high temperature and pressure rating, reducing maintenance frequency and improving overall system safety.Q: What surface treatments and packing options are available?

A: Surface treatment choices include black painted, galvanized, and sand blasted finishes for improved durability. The fittings are packed using export-standard methods, including wooden cases and palletization, to ensure safe and secure transport.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free